Poulin Grain’s Nutrition Experts Share Key Takeaways from the International Silage Conference

Poulin Grain Dairy Nutritionists (L to R) Paul Molesky, Melissa Carabeau, Dan Gingue, and Morgen Doane, attended the International Silage Conference to learn about the latest advancements in silage research for dairy herds.

The International Silage Conference is a worldwide meeting of silage experts, who gather to share breakthrough research and the latest recommendations for harvesting the highest quality silage for dairy cows. This week, four of our nutritionists attended the conference at the University of Florida in Gainesville.

Here’s what they think you need to know:

Take-aways from Morgen Doane:

Morgen is a dairy nutritionist who serves farms from Western VT to Eastern New York. This conference was important to Morgen because she feels that there is so much more that we still need to learn about silage to improve performance in our animals.

Benefits of a high-quality inoculant

Silage fermentation was, without a doubt, a huge focus of the meeting. Dozens of speakers showed the benefits of using a high-quality inoculant to improve feed stability and reduce dry matter loss. However, new research is showing an even larger advantage than we previously appreciated. Dr. Frank Mitloehner, from UC Davis, showed that the use of silage inoculants can reduce the release of volatile organic compounds that have a negative impact on air quality. Many speakers demonstrated that inoculants preserve energy in the silage, which can then be utilized by the cow instead. Dr. Heather Dann from Miner Institute shared that heifers prefer inoculated silage at 24 hours after defacing, compared to uninoculated at 24 hours, which could translate to improved intake when incorporating refusals into their ration. A small ruminant study even found that inoculated silages were related to improved udder health and milk quality in goats through changes in rumen metabolic pathways.

Baleage recommendations from the USDA Dairy Forage Research Center

By default, baleage undergoes a slower and less complete fermentation, with less lactic acid produced. For this reason, the baleage covering is critically important, and the recommendation is to use 7 layers of plastic that is at least 1mm thick. The ideal dry matter at harvest is 45-55 DM, but for small ruminants, slightly wetter bales reduce the risk of listeria. Additional recommendations include maximizing baleage density to at least 10lb of DM/ft3, using a lactic acid producing inoculant. Be mindful that heat increases plastic’s permeability to oxygen, so storing bales in shaded or cooler areas is advised when possible.

Aerobic stability during feed-out

Poor aerobic stability can result in wild yeast growth and reduced silage quality. What’s interesting is that the yeast is not often evenly distributed throughout the pile. In one study, the top layer (top 4%) of the bunk was 1000 times higher in yeast count than the bottom 96% of the bunk. When this layer is defaced and mixed with the whole pile, the feed turns out to be 100 times higher in yeast than the original bottom layer. This stresses the importance of good management of the top of the bunk, and feeding the top of the bunk to lower production animals or heifers whenever possible.

Top highlights from Paul Molesky:

Paul joined our nutrition team in 2020 after many years of experience managing a large dairy herd. As someone who has worked first hand with cows, he understands how important quality silage is to health, performance and profitability.

The latest in kernel processing

Corn silage processing is a clear advantage, but research and new recommendations continue to emerge. Research from a Brazilian consulting group, Tracking Feed, measured dry matter digestibility in corn kernels that were hand cut into halves, quarters, eighths, sixteenths, and thirty-seconds. The full potential of the corn kernel digestibility was not realized until the corn kernels were split in eights. This demonstrates the clear advantage of complete kernel processing, and that we can no longer rely on just breaking all kernels in half, or making sure they are all “knicked” for the cows to get the most out of your silage. Furthermore, Joe Lawrence, of Cornell Pro-Dairy, demonstrated that kernel processing score does not always improve after fermentation, so processing scores need to be excellent at harvest in order to guarantee excellent processing at feed out.

Rethinking the standards of haylage processing

It is critically important to harvest and process haylage adequately. Dr. Kenneth Klasheur, of the USDA Dairy Forage Research Center, shared his perspective on ideal forage processing, reiterating that shorter chop length forages can be fed to increase performance, while also maintaining health as part of a properly balanced diet. In fact, new research on Extreme Mechanical Processing of alfalfa, where the crop was ground in a hammer mill between harvesting and ensiling, showed an 8%-unit increased in total tract dry matter digestibility and an improvement in feed efficiency when fed to lactating cows.

Corn silage milk/ton calculations have been updated

One way to compare corn silage quality is through the milk per ton calculation. In 2024, this calculation was updated to more accurately reflect the higher component yields that we see in Holstein herds today. A few additional changes were made to the equation to improve its accuracy. This calculation can be found on the bottom right corner of our forage reports.

Take home messages from Dan Gingue:

Dan’s background in dairy financial management brings a clear perspective of how important quality forages are to a farm’s bottom line. For Dan, attending this conference was an investment in learning how to continue to push the bar higher in silage management.

Fungicides as an emerging opportunity

Fungicides are a common tool considered by farmers to reduce disease stress in corn silage. Dr. Phil Cardoso, from the University of Illinois, presented new research relating to the impact of fungicide on yield and quality. Dr. Cardoso’s work showed that when more than 10% of foliar disease is determined to be present when scouting a field, there is a 93% chance that fungicide will increase yield by at least 3 bushels per acre. Yield increase of over 8 bushels per acre have been seen, but only in 60% of treated fields.

Fungicides also result in taller plants, with a lower percentage of yellow leaves, and improved fiber digestibility when applied at the tassel stage. When silage was fed after shorter periods of fermentation, the lactic acid was higher in treated corn, but with a full 150 days of fermentation there was no difference in fermentation acids.

Silage safety is as important as ever

As an industry, we need to refocus on silage safety. Especially as silage storage piles get larger, the risk of a silage avalanche continues to increase. Using the buddy system or proper equipment, instead of approaching a bunk face on foot, improves safety. Care must be taken when cutting back plastic and removing tires from piles – and there is a need to develop more harness systems and/or platform solutions to reduce the risk of a fall. Additionally, silage gasses that are created during the first few days of ensiling can be very toxic, and farm personnel need to be trained to use caution when working around recently ensiled feeds.

Silage variety selection

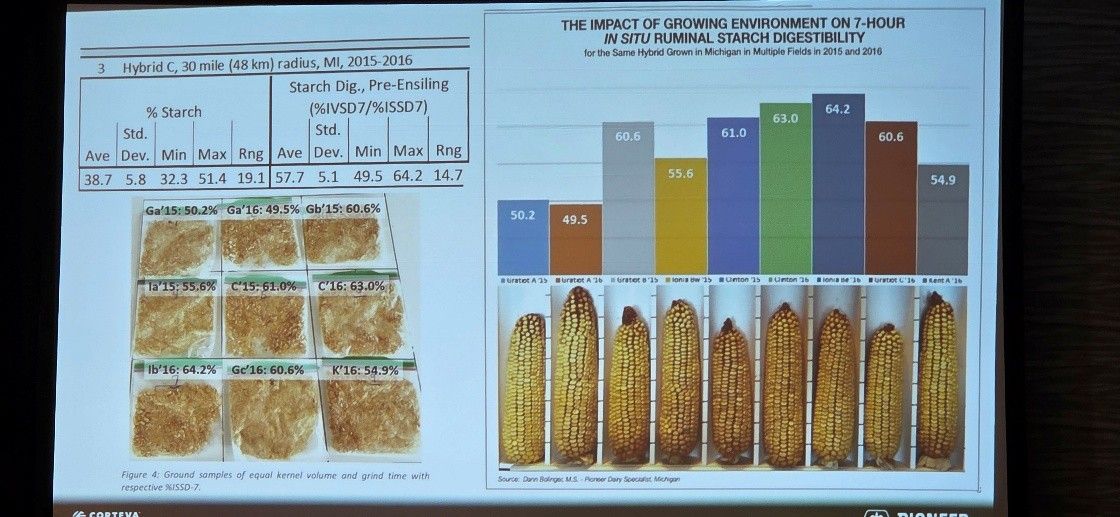

A series of speakers addressed the importance of choosing the correct silage variety for your farm. University of Florida’s, Dr. Marcello Wallau, reiterated that by choosing the right variety for your farm goals and environment, milk production can be improved by 15-30%. However, determining the correct varieties can be a challenge. In-field variation makes it nearly impossible to compare two varieties side by side. Dann Bolinger, from Pioneer, provided pictures (below) of corn grown from the same variety, in different fields, for two different years, and shows a wide range of ear development and starch digestibility. Many speakers recommended relying on large scale plot data or university trials to select the best hybrids for your farm.

Key highlights from Melissa Carabeau:

Melissa is our Director of Dairy Business, and a ruminant nutritionist by training. In her experience feeding cows, it is clear that the best diets and best performance require high quality forages. For Melissa, this conference was an investment in learning the latest silage research that is applicable to our customer’s farms.

Novel lab analyses to troubleshoot silage issues

Despite the farmer’s efforts, sometimes silage fermentation doesn’t go according to plan. Richard Scuderi, a scientist at the Lallemand Research Center at the Miner Institute, is utilizing high-throughput genetic tests to identify the presence of various bacterial and fungal communities in silage. His work shows that as silage quality differs, the microbial populations that live in the silage change as well. In the future, this work may be a critical tool of troubleshooting silage issues and determining the appropriate response to maintain health and productivity in the cows.

Silage for drought conditions

We typically have enough water in the Northeast—sometimes more than enough! However, in some areas, dry conditions are starting to become a reality. One approach we can learn from our neighbors in the Southwest is to plant sorghum during dry summers. Sorghum uses 45% less water than corn silage. When rainfall totals are less than 23 inches during the growing season, sorghum silage can actually out-yield corn silage. Brown mid-rib (BMR) sorghum is more digestible than conventional varieties and will likely be a better fit in lactating cow diets.

The economics of silage shrink

Dr. Heather Dann, from Miner Institute, presented on how applying a silage inoculant at harvest can improve fermentation and reduce shrink by minimizing dry matter loss and spoilage. Shrink results from both dry matter losses during fermentation and the removal of spoiled silage at feed-out. In their study, the use of an inoculant reduced fermentation shrink from 4.1% to 3.4%, and total shrink from 28.6% to 16.4%. While the small experimental bunks may experience more shrink than larger commercial systems, this level of loss would still cost a farm $793 for every 100 tons of harvested silage, based on a value of $65 per ton.